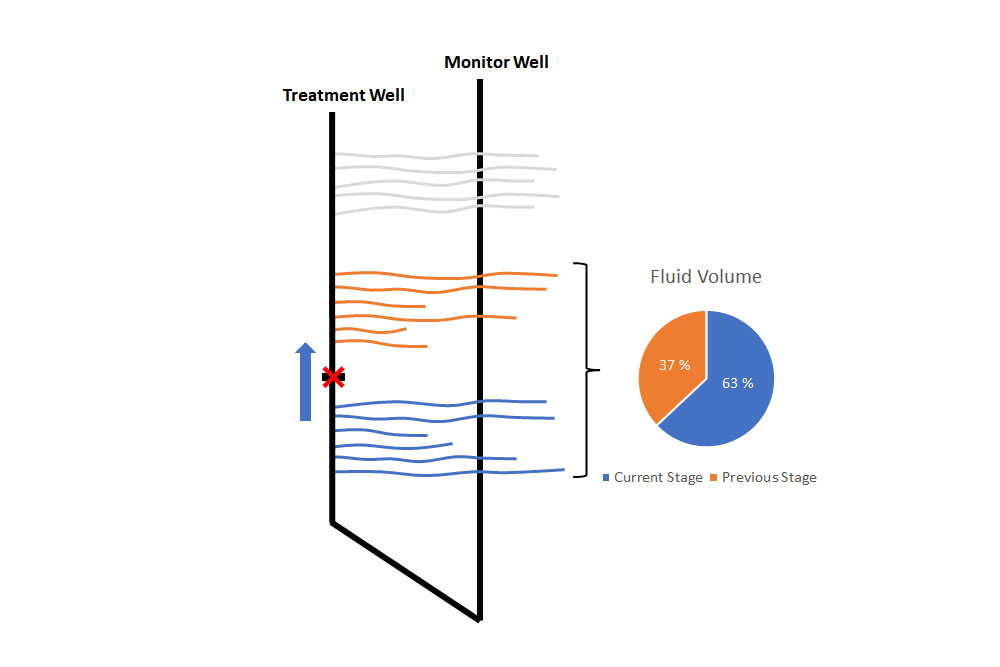

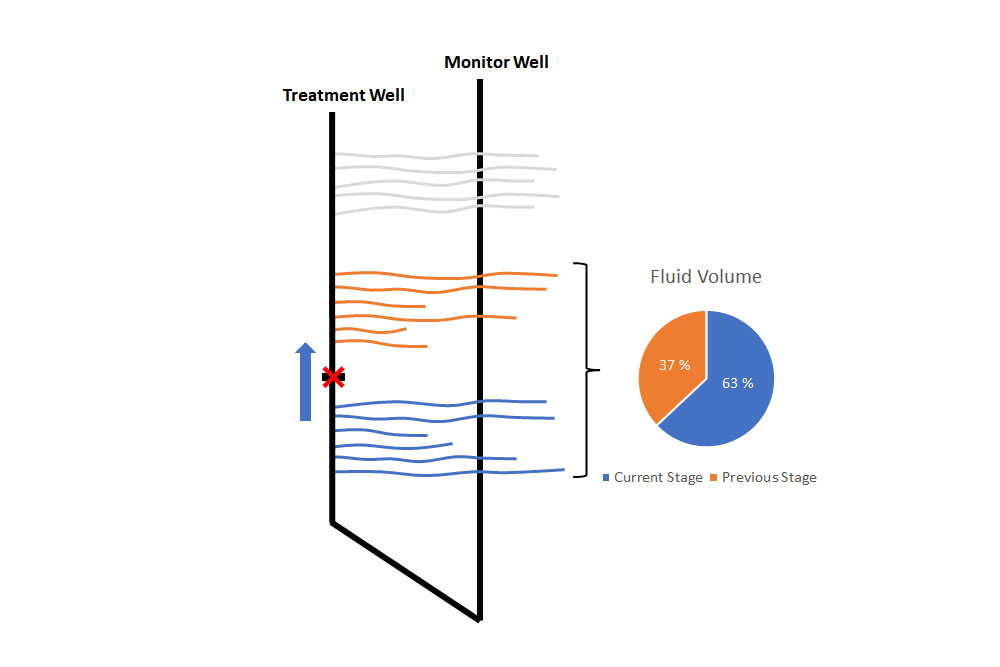

Injection volume estimation using calculated fracture width

IFDATA LLC recently completed a large-scale hydraulic fracturing analysis with the objective of evaluating various completion design configurations and identifying the optimal parameters leading to improved completion cost and economic development for the client. The well-pad consisted of several unconventional wells located in the resource rich Eagle Ford Shale. The primary dataset included Low-frequency Distributed Acoustic Sensing (LF-DAS) data acquired from multiple offset wells instrumented with temporary optical fiber. LF-DAS recorded inter-well fracture communication events from over 100 treatment stages originating from multiple injection wells and various completion designs.

During the analysis there were observed signals in the LF-DAS associated with reactivated fractures from previous adjacent stages, indicating the loss of zonal isolation. Common LF-DAS analysis is generally limited to the qualitative description of inter stage communication severity. However, the application of IFDATA’s unique Quantitative Fracture Width Analysis provided an advanced level of information leading to actionable insights for the operator. The magnitude of the reactivated fracture widths compared to the new fracture widths provided engineers with a rapid, first order level of quantitative information describing the severity of inter stage communication. Assuming a relationship between fracture geometry and injection volumes, IFDATA developed a model to derive the amount of fluid volume associated with reactivated fracture width calculations. This fracture derived volumetric analysis provided the client with critical information to 1) assess the economic risk associated with poor stage isolation, and 2) determine if a follow-up study is necessary to identify if the mechanisms driving poor isolation are due to well construction and well design.