Quantitative Evaluation of Completion Designs using Cross-well Strain Measurements

At a Glance

The Challenge

- Developing cost-effective monitoring techniques

- Cross-well strain limited to qualitative interpretations

The Solution

- IFDATA’s quantitative cross-well strain analysis

- Calculate hydraulic fracture widths

- Identify designs driving even fracture growth

Added Value

- Better understanding of fracture geometry

- Determination of optimal completion design

- Low-cost surveillance

The Challenge

Economic development of unconventional wells requires careful consideration of monitoring equipment, data analysis, and well intervention costs. The utilization of Low-Frequency Distributed Acoustic Sensing (LF-DAS) for cross-well strain measurements is a cost-effective surveillance technique to monitor far-field fracture development during hydraulic treatments. However, the full potential of LF-DAS has been hindered by limited quantitative analysis, as it is mainly confined to qualitative interpretations.

This case study addresses the challenge of developing a quantitative solution to assess completion designs using cross-well strain measurements, offering operators a low-cost surveillance option to evaluate well completion programs.

The Solution

IFDATA uses a novel geomechanical inversion algorithm to calculate the hydraulic fracture width using cross-well data from two monitoring wells. Over 100 treatment stages were analyzed including various completion designs implemented across three treatment wells. A key metric called “Fracture Unevenness” was developed to determine the non-uniformity of inverted fracture widths, indicating optimal completion designs with more even far-field fracture growth.

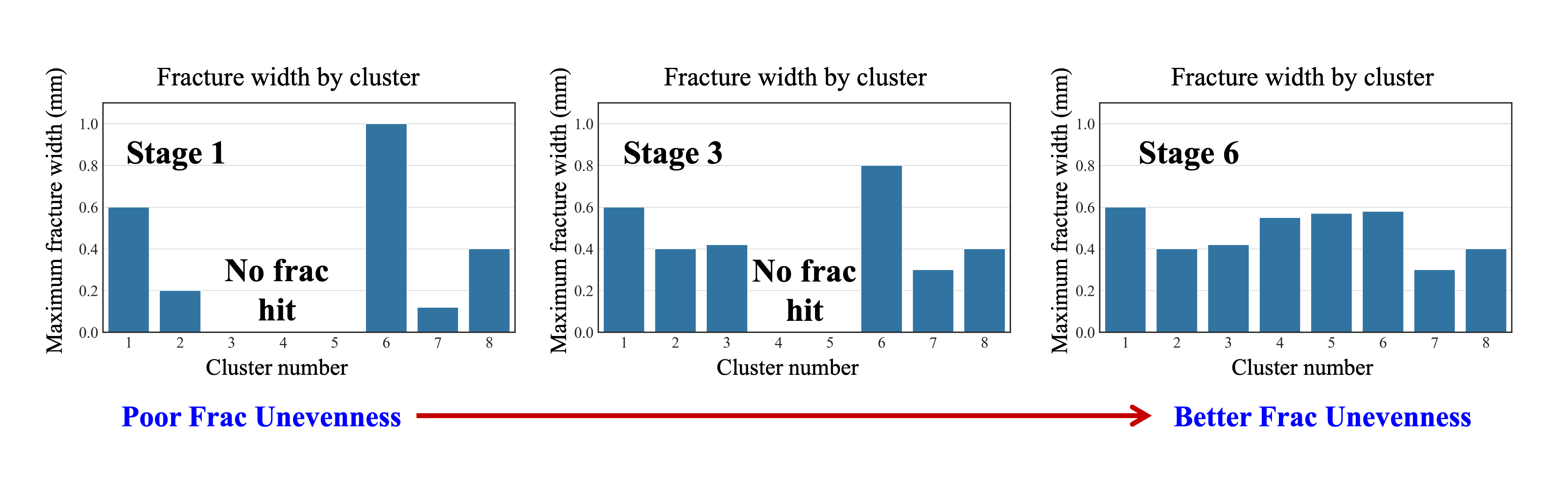

Conceptual representation of fracture widths for three stages. Optimal Fracture Unevenness is associated with better cluster efficiency and the uniformity of fracture widths.

The Results

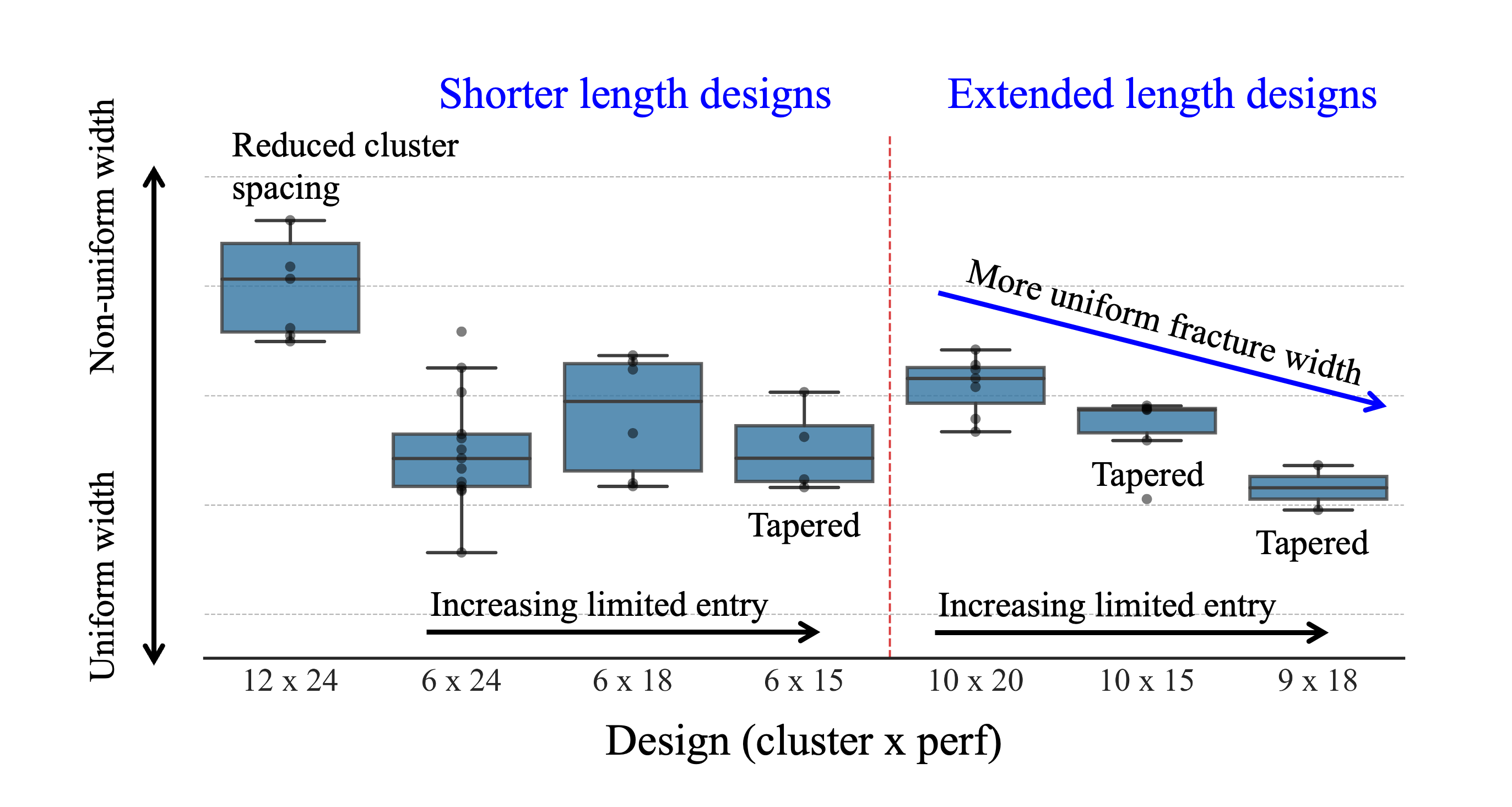

Fracture Unevenness was integrated with several other cross-well strain derived attributes to determine the impact of design variations including different stage lengths, clusters per stage, and tapered perforation applications. The cross-well strain data shows that:

- Extended stage length (nine and ten cluster) designs benefited from more aggressive limited entry and tapered design practices.

- The 12 x 24 reduced cluster spacing design consistently resulted in the most uneven fracture growth.

- Far-field fracture geometry is influenced by completion design and fracture placement.

Fracture Unevenness results for each stage grouped by design. Stages with more uniform fracture widths are associated with a lower Unevenness value.

Added Value

By integrating IFDATA’s quantitative fracture width analysis with standard qualitative cross-well strain attributes, a more advanced level of information becomes available to identify the efficiency of different completion designs. Operators can optimize their completion programs by reducing cluster count and adopting tapered perforation configurations, especially for longer length designs. Additionally, knowledge of fracture width is crucial for optimizing proppant size and transportation, enhancing overall completion effectiveness.